3.1. Characteristics of basic copper carbonate manufacture

In order to prepare basic copper carbonate, the first step reaction product in the copper (II) oxide production process using the two step chemical reaction, NaClO3 type etching wastes were used as the reaction mole ratio of sodium carbonate.

Fig. 1 shows the particle size analysis of basic copper carbonate produced according to the molar ratio of NaClO

3 type etching wastes to sodium carbonate. The D50 values were 35.69 mm, 38.66 mm, 48.41 mm, 49.36 mm, 44.10 mm, and 36.88 mm for reaction mole ratio of 1.08, 1.20, 1.32, 1.44, 1.68, and 2.04, respectively. Also the SPAN values, indicating distribution of particles, were 1.653, 0.871, 0.763, 0.712, 0.781, and 1.068 for reaction mole ratio of 1.08, 1.20, 1.32, 1.44, 1.68, and 2.04, respectively. From this figure, it was confirmed that particle size increases and decreases with increasing reaction mole ratio. Also, the SPAN value decreased with increasing reaction mole ratio. When the reaction mole ratio was 1.08, the particle size was the smallest. It was confirmed that the SPAN value is broadest in the largest particle distribution. The lower the reaction molar ratio, the more the sodium chloride-based etching waste solution is used and the lower the pH (= 6.3) due to the high content of copper chloride in the etching solution and the hydrochloric acid. By decomposing the particles of basic copper carbonate produced, it is considered that the average particle size is small and the particle distribution is broadly formed together. In the case of the reaction molar ratio of 1.20, as the reaction molar ratio is 1.08, the amount of the sodium chlorate-based etching waste solution is larger than that of the sodium carbonate, so that the pH value of 7.1 is relatively low so that some of the particles are destroyed and the average particle size becomes smaller, and the particle distribution is also broadly formed. The reaction mole ratio of 1.32 was also found to be small as the reaction mole ratio increased and the particle size increased. This means that the particle distribution is formed relatively narrowly. When the reaction mole ratio was 1.44, the particle size was the largest and the SPAN was the smallest. When the reaction mole ratio was 1.68, the particle size decreased again and the SPAN value also increased. When the molar ratio of sodium carbonate is low, the value of m in basic copper carbonate [

mCuCO

3·

nCu(OH)

2] becomes larger than

n, and when the molar ratio of reaction is high, the value of

n becomes large, so that the alkaline ratio is high and thus changed the particle size of the basic copper carbonate[

11].

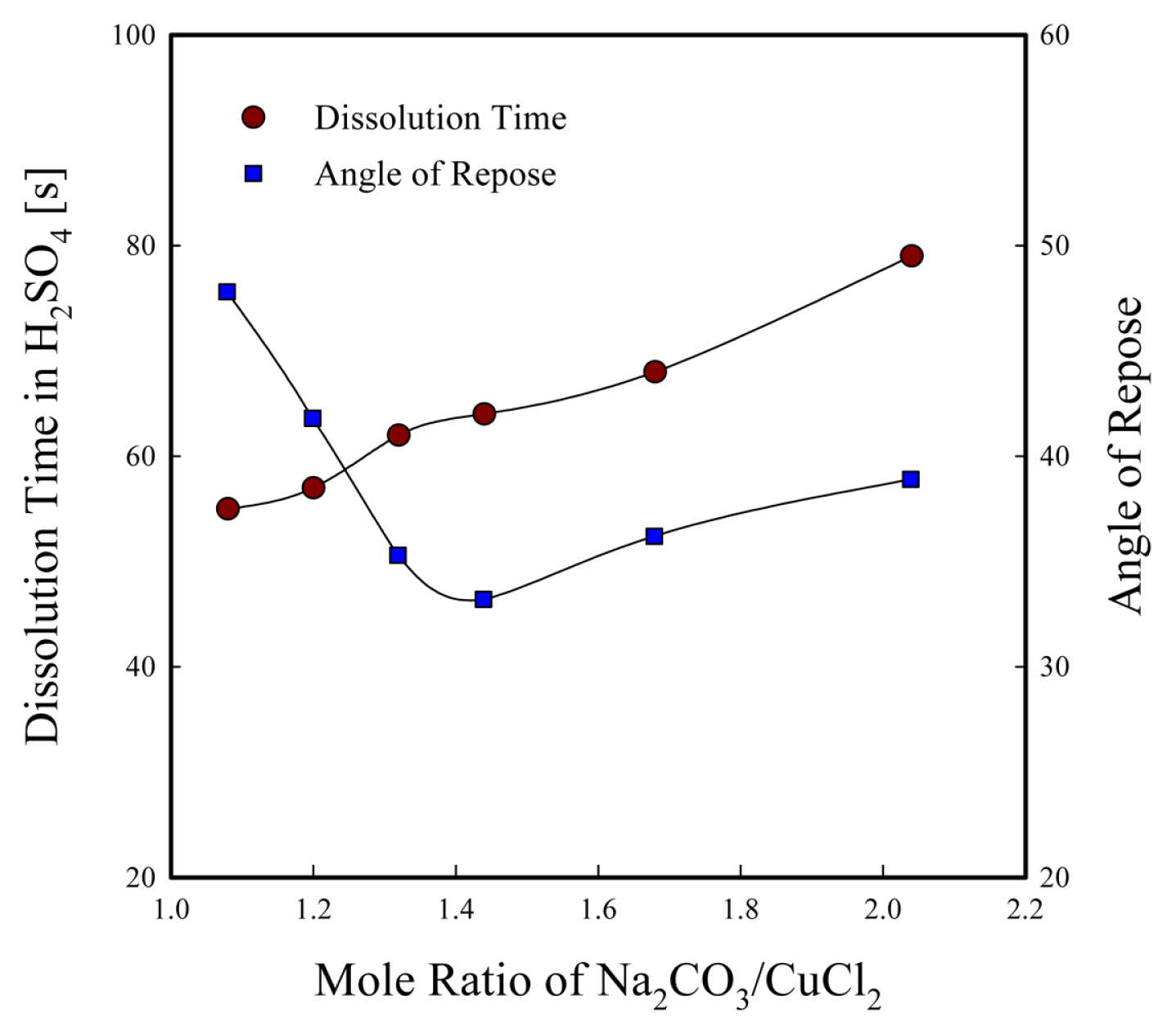

Fig. 2 shows the solubility to sulfuric acid and the repose angle of basic copper carbonate prepared according to the molar ratio of NaClO

3 type etching wastes and sodium carbonate. With increase of the reaction molar ratio, the solubility of basic copper carbonate in the first reaction increased with sulfuric acid. Also, the repose angle of the basic copper carbonate produced decreased with increasing reaction molar ratio. The apparent specific gravity tended to increase with increasing reaction molar ratio and then decreased. The apparent specific gravity tended to increase with increasing reaction molar ratio and then decreased. The dissolution time to sulfuric acid was the shortest in the range of 55~57 second for the reaction molar ratio of between 1.08 and 1.20. the dissolution time to sulfuric acid was increased as the reaction molar ratio increased. The longest reaction time was 79 second at the reaction molar ratio of 2.04. It is considered that the dissolution time is fast due to the low content of copper and the short reaction time with sulfuric acid due to the inclusion of some basic copper chloride compound in the range between 1.08 and 1.20 where the reaction molar ratio is low. As the reaction molar ratio increases, the reaction time with sulfuric acid increases as the content of copper increases. In the case of repose angle, when the reaction mole ratio was at the range between 1.08 and 1.20, it was measured at 41.8° ~ 47.8°, which indicates poor flowability of the powder. This is because the pH is lowered by the copper chloride (II) and hydrochloric acid present in the NaClO

3 type etching wastes, so that the generated particles of basic copper carbonate are decomposed to form particles having a small size, high repose angle due to wide range of distribution, and the low specific gravity of 0.72 ~ 0.90. From the reaction molar ratio above 1.32, the repose angle tended to decrease. This is because the amount of sodium chlorate-based etching waste solution usage in sodium carbonate is decreased, and the decomposition ratio of particles is low due to strong acid so that constant particle shape has progressed. When the reaction molar ratio was 2.04, the tendency of the particles to become fine particles due to alkalinity was confirmed even when the amount of the hydrogen peroxide-based etching waste solution used for sodium carbonate was excessive. For this reason, when the particles are formed too small, the repose angle is high and the flowability of the powder is lowered, and thus the apparent specific gravity also tends to decrease. The particle size is related to the repose angle and the apparent specific gravity. It is well known that the average particle size of the basic copper carbonate, the primary product, is low, because the repose angle is increased. At the reaction mole ratio of 1.44, and the repose angle and the apparent specific gravity were 33.2° and 1.28, respectively. This suggests that the optimum conditions for the reaction of the sodium peroxide with the hydrogen peroxide etching waste solution are shown. The repose angle is less than 36° indicates very good flowability. Therefore, the raw material can be supplied constantly by flowing down the powder at the time of measurement. If it is more than that, a driving force is required. At the molar ratios of 1.32 and 1.62, the repose angle was 35.3° and 36.2°, respectively. When the repose angle was measured, it was confirmed that the powder was falling down by itself. For the reaction molar ratios of 1.08, 1.20, and 2.04, the repose angle was 47.8°, 41.8°, and 38.9°, respectively. In this case, since the repose angle is 36° or more, it can be confirmed that it is physically supplied and measured. Therefore, the optimum molar ratio of sodium carbonate to the reaction molar ratio of sodium carbonate based on the particle size of basic copper carbonate, dissolution time to sulfuric acid, and repose angle, 36° or less, was 1.44.

3.2. Fabrication characteristics of copper (II) oxide

In this paper, sodium hydroxide was added to 300 g of basic copper carbonate, Cu content of 58.3 wt.%, sodium hydroxide prepared at a reaction molar ratio of 1.44 NaClO

3 type etching wastes and sodium carbonate at reaction temperature of 80°C. The usage of sodium hydroxide was varied in the range of 60 g to 200 g.

Fig. 3 shows changes in CuO content and chloride ion concentration of copper (II) oxide prepared according to the sodium hydroxide usage. The CuO contents were 93.6 wt.%, 95.5 wt.%, 96.0 wt.%, 96.6 wt.%, 97.0 wt.%, and 97.4 wt.%, for sodium hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 200 g, respectively. Also the pH values were 9.5, 10.2, 10.7, 12.4, 12.7, and 12.8, for sodium hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 200 g, respectively. It was confirmed that the CuO content and the pH were increased as the use amount of sodium hydroxide was increased. In addition, the basic copper carbonate produced had a chloride ion content of 198 mg/L, which can be reduced by using an alkali solution, such as sodium hydroxide. The chlorine ion contents were 28.5, 20.7, 12.5, 9.7, 13.7, and 16.2mg/L for sodium hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 200 g, respectively. From those results, it can be deduced that the chloride ion concentration decreased and increased as the amount of sodium hydroxide was increased. This is because, in the case of basic copper carbonate, the chlorine ion attached to the surface can be removed during washing the basic copper carbonate, but the chlorine ion contained therein is hardly removed. This means that sodium hydroxide is used to decompose basic copper carbonate and convert it to copper oxide (II), which is effective in removing chlorine ions. The sodium hydroxide usage should be optimized during the process. When sodium hydroxide usage was 60 to 80 g, it was converted into copper oxide (II), but the content of copper oxide (II) was measured to be low. It is considered that chlorine ions are present at a high level of 20.7 to 28.5 mg/L because some of them remain unconverted. When sodium hydroxide was used more than 100 g, chlorine ion was decreased slightly, it was 12.6 mg/L. When sodium hydroxide usage was 120 g, the best result was obtained as 9.7 mg/L. The chlorine ion content was increased again higher than 160 g of sodium hydroxide usage. From those results, when sodium hydroxide usage was 160 g or more, there was difficult to the decomposition of chlorine ion, the pH was increased so that unnecessary washing water is increased, and the residual chlorine ion is increased again. Therefore, it may be deduced that the optimum sodium hydroxide usage for converting basic copper carbonate into copper (II) oxide is 120 g, which has the lowest level of CuO content of 96.6 wt.% and chlorine ion of 9.7 mg/L.

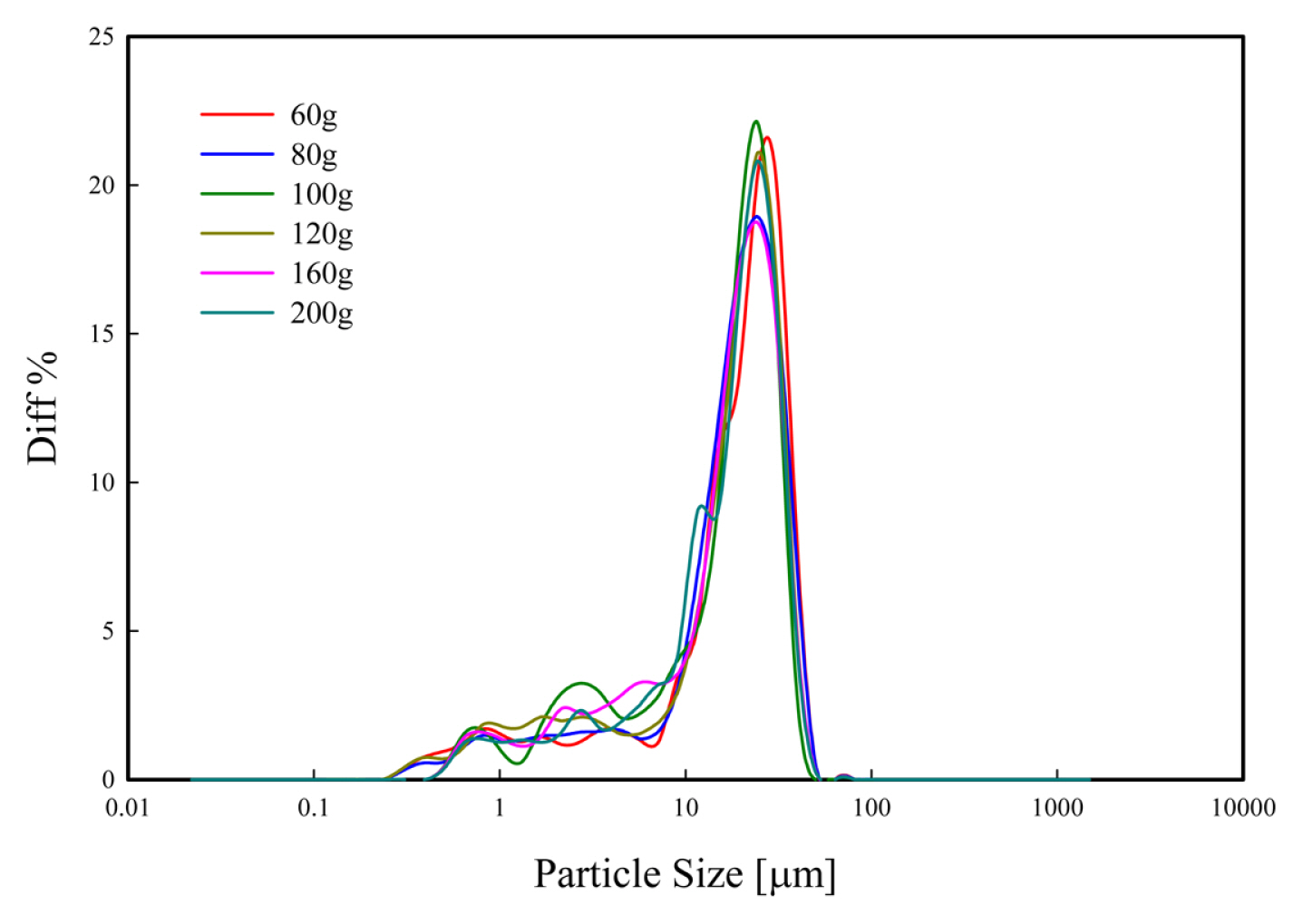

Fig. 4 shows the particle distribution of copper (II) oxide produced according to the amount of sodium hydroxide. As the amount of sodium hydroxide increased, the particle size decreased and the SPAN value increased slightly. The D50 values were 21.09 mm, 19.46 mm, 19.02 mm, 19.49 mm, 18.38 mm, and 18.01 mm for hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 200 g, respectively. Also the SPAN values, indicating distribution of particles, were 1.462, 1.508, 1.511, 1.551, 1.584, and 1.590 for hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 200 g, respectively. When sodium hydroxide with strong alkalinity is used for converting from basic copper carbonate into copper (II) oxide, during the decomposition of basic copper carbonate into copper (II) oxide and carbonate (CO

3−), the average particle size of basic copper carbonate decreased from 49.36 μm to 18.01 ~ 21.09 μm. It is considered that when the molecular weight of basic copper carbonate

mCuCO

3·

nCu(OH)

2 is decomposed by sodium hydroxide (

m+

n)CuO is formed, resulting in a smaller molecular weight and smaller particle size. In the case of basic copper carbonate, the SPAN value was as small as 0.712, and the particle distribution was densely formed. However, after the second step reaction, the copper carbonate was decomposed and the SPAN value was widely distributed in the range of 1.462 ~ 1.590. Therefore, from the particle size and particle distribution analysis results, as the sodium hydroxide usage was increased, the particle size of copper (II) oxide was small and the particle distribution was wide due to the decomposition of copper carbonate.

Fig. 5 is a scanning electron microscope (SEM) image showing the shape change of copper (II) oxide particles produced according to the amount of sodium hydroxide used. When sodium hydroxide was used at 60 g and 80 g, the particle size was not significantly changed from the particle structure formed in the copper carbonate. However, when the amount of sodium hydroxide dosage was more than 100 g, it was confirmed that the particle structure of the surface layer was slightly broken from the spherical shape, but the shape of the particle was not largely changed. As shown in this figure, it may be confirmed once again that there is no significant difference in particle size according to the sodium hydroxide dosage. In case of sodium hydroxide, which is a strong alkaline substance, when basic copper carbonate is converted to copper oxide (II), basic copper carbonate is decomposed copper (II) oxide and carbonate (CO

3−), when the amount of sodium hydroxide used in the powder is more than 100 g, it is considered that the shape of the particles is converted into copper oxide (II) without any significant deformation. Therefore, the sodium hydroxide in an amount of 100 g or more did not change the shape of the particles.

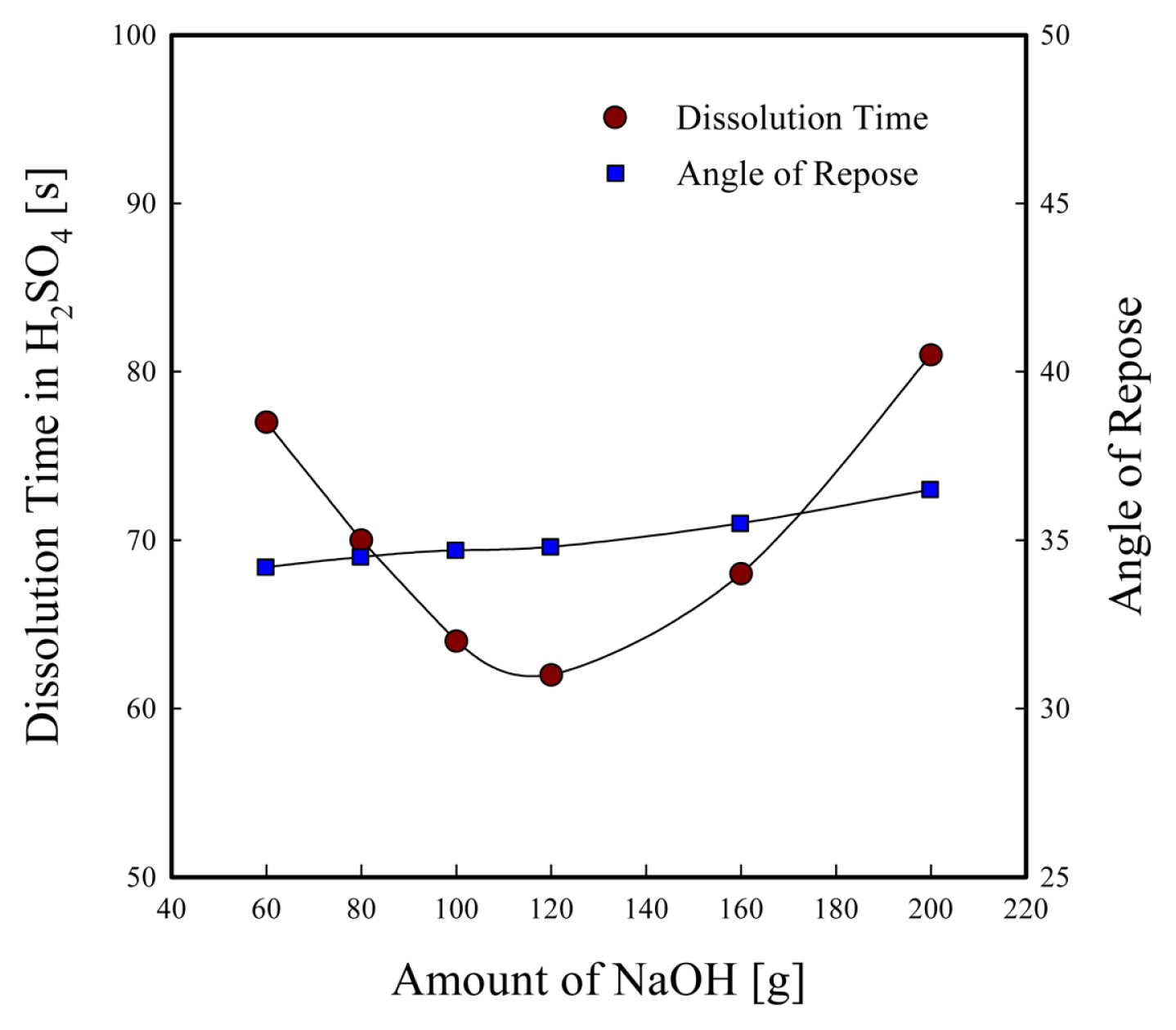

Fig. 6 shows the solubility and repose angle of copper (II) oxide prepared according to the sodium hydroxide dosage. The dissolution time for sulfuric acid decreased with increasing use of sodium hydroxide, and increased to 62 seconds at 120 g of sodium hydroxide usage, and then increased again with increase of sodium hydroxide usage. The dissolution time to sulfuric acid were 77, 70, 64, 62, 68, and 81seconds for the sodium hydroxide usage of 60 g 80 g, 100 g, 120 g, 160 g, 180 g, respectively.

The dissolution time to sulfuric acid of basic copper carbonate, the first reaction product, was 64s.

The dissolution time to sulfuric acid of copper (II) oxide, the second reaction product, was higher than that of the first reaction product when sodium hydroxide was used in an amount of 80g or less and 160 g or more. However, at sodium hydroxide usage of 100 to 120 g, it was found that the similar time was increased in the range of 62 to 64 seconds. The values of repose angle were 34.2°, 34.5°, 34.7°, 34.8°, 35.5°, and 36.5° for sodium hydroxide usage of 60 g, 80 g, 100 g, 120 g, 160 g, and 180 g, respectively. As sodium hydroxide usage was increased, the repose angle of copper (II) was slightly higher than that of basic copper carbonate, 33.2°. However, the result satisfies criteria of flowability, 36° or less, which represents that the hydroxide usage rarely affects the flowability of the powder. It is confirmed that, when the basic repose angle of basic copper carbonate is used, most of the original repose angle is maintained in the flowability of the powder even if the particle size is small due to sodium hydroxide.